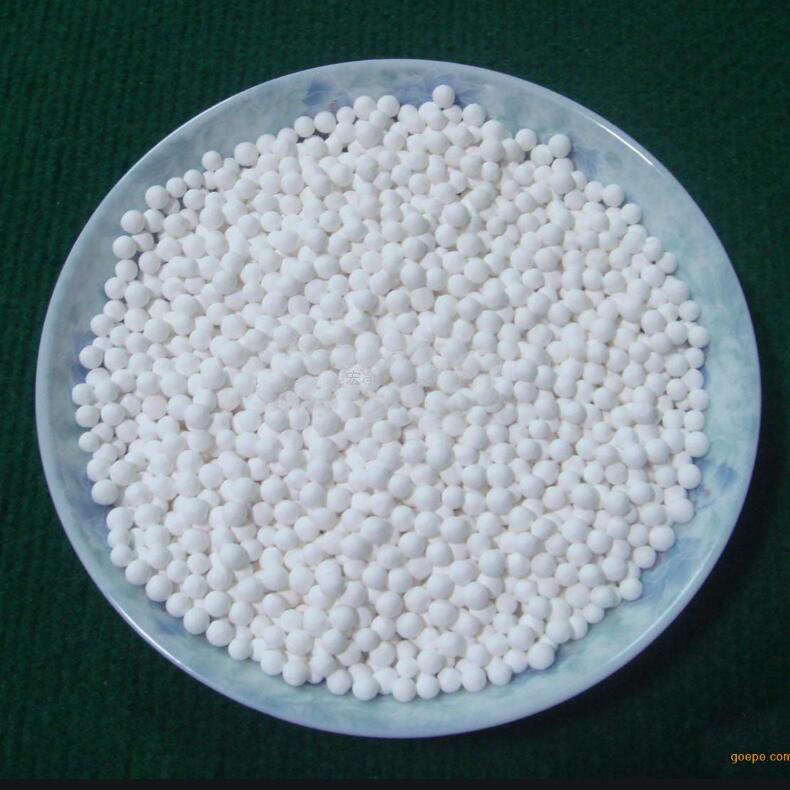

E.P.S. (Expandable Poly-Styrene) is a lightweight, rigid, plastic foam insulation material produced from solid particles of polystyrene. Expansion is achieved by virtue of small amounts of pentane gas dissolved into the polystyrene base material during production. The gas expands under the action of heat, applied as steam, to form perfectly closed cells of EPS. These cells occupy approximately 40 times the volume of the original polystyrene bead. The EPS beads are then molded into appropriate forms suited to their application. Products made from foamed polystyrene are nearly ubiquitous, for example packing materials, insulation, and foam drink cups .

Features

l High strength,

l Fast forming,

l High foaming & oxygen index.

Fire Retardant Grade

|

Specification |

F301 |

F302 |

F303 |

F401 |

|

|

Beads Size mm |

1.00-1.60 |

0.85-1.25 |

0.70-0.90 |

0.50-0.80 |

|

|

Vol.Cont % |

6.85 |

6.8 |

6.66 |

6.27 |

|

|

H2O % |

0.95 |

1.12 |

1.25 |

1.26 |

|

|

F.M % |

≤0.10 |

≤0.10 |

≤0.10 |

≤0.10 |

|

|

Avg.size mm |

1.32 |

1.01 |

0.8 |

0.63 |

|

|

PRE-EXPENSION DENSITY |

12.0-14.0 |

14.0-16.0 |

15.0-18.0 |

18.0-25.0 |

|

|

Sieving ≥ 95% |

95.0 |

95.0 |

95.0 |

95.0 |

|

|

Result(g/l) |

13.67 |

15.18 |

17 |

23.22 |

|

|

|

Max(I) |

12.58 |

14.58 |

16.67 |

19.00 |

|

DENSITY |

(g/l) |

||||

|

RANGE |

Mix(I) |

14.00 |

16.00 |

18.00 |

24.33 |

|

|

(g/l) |

||||

|

Oxygen Index |

≥30 |

≥30 |

≥30 |

≥30 |

|

EPS F Series features with high strength, fast forming, high foaming & oxygen index. It can be used in a wide variety of applications including general insulation, fabrication, blocks for panels, general & protective packaging, as well as insulated concrete forms and thin walled custom molding.

Our factory

“Strength builds the foundation, and excellent services reach all over the world.” Create win-win situation with customers

Leave A Message

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.